Qualisteel’s commitment to innovation will be taken to Metalurgia, where the company will be highlighting its precision casting solutions, also known as investment casting or lost wax casting. Recognized for the high quality of its products and its compliance with strict international standards, the company stands out as a reliable partner in the development of customized and sustainable solutions.

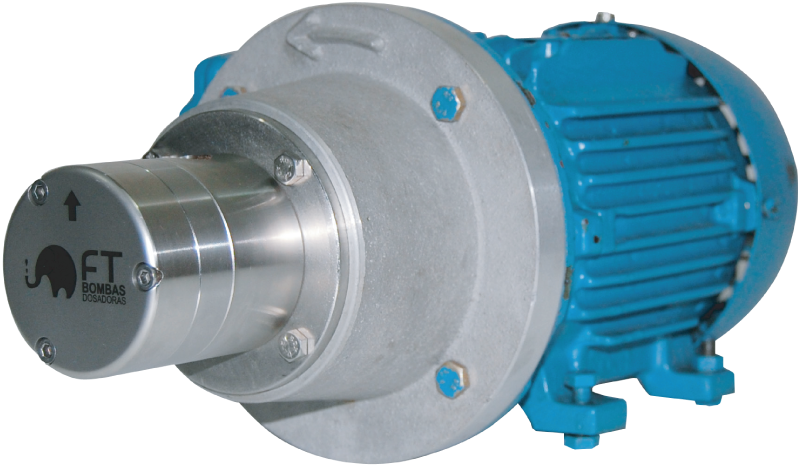

Precision casting is an advanced technology that allows complex parts to be manufactured with extremely high precision, excellent surface finish and efficient use of materials. This industrial process is widely adopted in sectors such as agriculture, road transport, automotive, nautical and food, due to its ability to produce components with detailed geometries and superior mechanical properties. Qualisteel has mastered this technique, offering customized and competitive solutions for the most varied market demands.

Qualisteel works with a wide range of metal alloys to meet different applications and specific customer needs in precision casting processes. Among the materials available are carbon, low and medium alloy steels, austenitic stainless steels, martensitic stainless steels, precipitation-hardenable stainless steels and tool steels. This versatility allows the company to produce high-performance parts, adaptable to different environments and operating conditions.

QUALITY IN PRECISION CASTING

Qualisteel follows a strict quality control process at every stage of precision casting manufacturing, from the selection of raw materials to final delivery. Certified to ISO 9001, the company ensures that all its products meet international standards and the specific requirements of its customers. The use of modern technologies and efficient management practices allows Qualisteel to offer products with high dimensional accuracy, excellent surface finish, optimized mechanical properties and compliance with global technical standards.

Qualisteel excels in the manufacture and supply of steel parts and products through precision casting. With an unwavering commitment to quality, the company strives to exceed market expectations, contributing to the success of its partners and promoting the sustainable development of the industry.

ABOUT QUALISTEEL

Located in Nova Prata/RS, in the Serra Gaúcha, Qualisteel began its activities in 1988. With over 35 years of history, it specializes in the microfusion process. With a production capacity of 100 tons/month, the company serves both the domestic and foreign markets, supplying high quality parts and components.

Qualisteel is recognized for its excellence in manufacturing tailor-made products according to its customers’ technical specifications. ISO 9001 certified, the company maintains a constant commitment to quality, innovation and sustainability, consolidating its position as a benchmark in the industrial precision casting sector.