A global authority in Optical Emission Spectrometry (OES), Metal Power Analytical showcases its products and analytical solutions at Metalurgia 2025. The company’s instruments help determine the accurate chemical composition of metal alloys, down to parts per million (ppm), serving as a crucial asset in quality control, production monitoring, research, and compliance. Their customers span critical sectors such as automotive, aerospace, defence, foundries, metal recycling, and manufacturing, making Metal Power Analytical a trusted name globally.

At the fair, Metal Power Analytical will display the industry’s most comprehensive range of OES instruments, including Stationary Arc/Spark OES, Mobile OES, Rotating Disc Electrode (RDE) OES, and a host of allied equipment and digital Industry 4.0 tools. Visitors will have the opportunity to see these solutions up close and gain insights into how each one addresses real-world challenges in elemental analysis.

METAL ANALYSIS SOLUTION

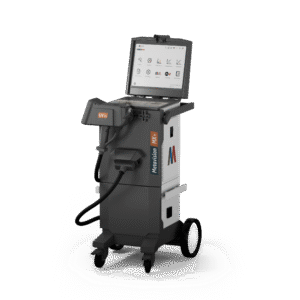

Among the highlights is the Metavision-10008X, Metal Power Analytical’s flagship R&D-grade spectrometer, designed for ultra-accurate applications. Capable of detecting over 60 elements at single and sub-ppm levels—including gaseous elements such as Oxygen, Hydrogen, and Nitrogen—this instrument is tailored for high-performance laboratories and advanced alloy research. For industries requiring a balance of performance and cost-efficiency, the Metavision-1008i3 delivers powerful functionality for soluble-insoluble separation, copper purity, and gaseous analysis like hydrogen detection in titanium.

Notably, Metal Power Analytical will also be demonstrating the Metavision-8i, a segment-leading dual-optics OES designed especially for MSMEs that don’t want to compromise on features while being budget-conscious. This model proves that high-quality, accurate metal analysis is no longer out of reach for smaller companies. Further, their mobile OES, the Metavision-MX+ & Metavision-MX, provide analysis on the go, making them suitable for heavy-duty PMI, alloy verification, and scrap metal analysis. For foundries, casting units, and budget-conscious operations, the MOSS spectrometer offers elemental detection down to 50 ppm at an entry-level price point, ensuring that no user is left behind in the quality revolution.

HIGH TECHNOLOGY FOR OPTICAL EMISSION SPECTROMETRY

What sets Metal Power Analytical apart isn’t just its impressive portfolio, but its commitment to innovation, scalability, and user-friendliness. The company’s technologies for Optical Emission Spectrometry incorporate CMOS detector-based optics for ultra-high accuracy, dual optics systems for effective detection of difficult gaseous elements, and sealed, thermally stabilised designs that eliminate the need for vacuum systems, drastically reducing maintenance and cost of ownership.

Another standout feature is SmartSTD, a proprietary technology that enables users, even first-timers, to standardise an instrument using just a single sample within five minutes. This capability removes one of the biggest barriers to adoption: the need for extensive training and expertise.

ABOUT METAL POWER ANALYTICAL

With over three decades of excellence in elemental analysis, the company will be presenting its prominent Optical Emission Spectrometers and allied technologies, offering demonstrations of systems that promise to revolutionise metal testing and elemental analysis across industries. The company continues to lead in its field with its robust CARE support program. Offering predictive maintenance, uptime assurance, remote diagnostics, and tailored AMC packages, the company ensures peace of mind and minimal operational risk for its customers. Whether it’s routine service or urgent troubleshooting, Metal Power Analytical provides reliable, responsive assistance globally.