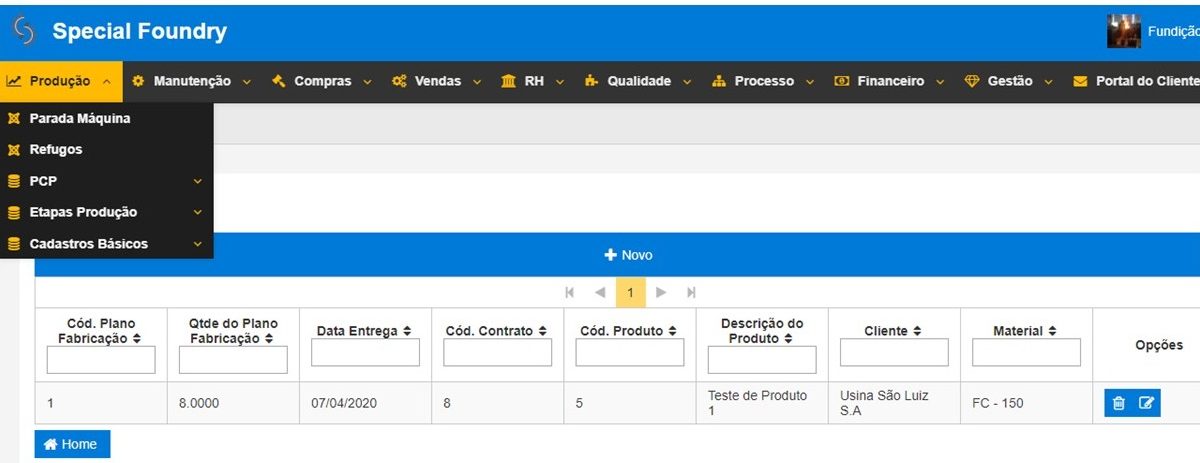

The online ERP created specifically for the foundries by Special Foundry will be officially launched by the company at Metalurgia 2020. The online version of the system uses the concept of the Industry 4.0, which allows controlling the production and/or processes. The evolution of the Special Foundry’s online ERP operates in the cloud, with access remote, allowing the manager real-time integration with encrypted access control, assuring higher yield.

The online ERP created specifically for the foundries by Special Foundry will be officially launched by the company at Metalurgia 2020. The online version of the system uses the concept of the Industry 4.0, which allows controlling the production and/or processes. The evolution of the Special Foundry’s online ERP operates in the cloud, with access remote, allowing the manager real-time integration with encrypted access control, assuring higher yield.

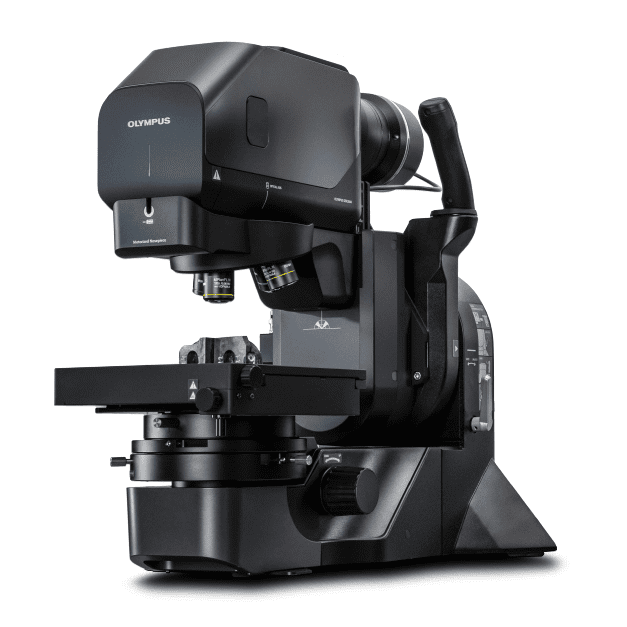

The ERP allows the integration of alloy weighing equipment with control via web platform, that is, using a web browser. It also favors the connectivity among collaborators, machines, and the ERP itself, facilitating the identification of faults, logs, corrections, or possible interruptions of the production.

Special Foundry’s specific ERP to foundries has been used in foundries and micro casting operations, regardless of the cast material, since the software structure covers the management needs of these companies.

Online ERP for Industry 4.0

Special Foundry’s online ERP is suitable to the Industry 4.0 concept and allows the entry of new technologies that optimize the production and the control of processes. It is a technology for the future of the foundries so that they remain competitive in the market, using tools that offer greater yield and reduced cost and waste.

The ERP was developed by a team of professionals of Special Foundry with expertise in metallurgy and with a vast experience in the segment in the areas of management, production, and foundry processes. In addition to investing continuously in the improvement of the system, Special Foundry counts on a technical team for face-to-face or online support and training at customers, in addition to the possibility of technical support in the metallurgic area to develop solutions and improvements for the foundries.

How it all started

Special Foundry’s ERP was developed based on the need of foundry managers in having a customized tool for this market. With the system, it is possible to collect real, instantaneous data, with interaction of control of production and processes. In addition to implementing the system, the company counts on a team of technical support for face-to-face or online training programs, contracts of technical support in the metallurgic area, both for solutions and to improvements in the processes.