Specialized in the manufacture of analytical instruments and mechanical testing and inspection equipment, global leader Shimadzu launches in Metallurgy the HMV-G microdurometer and the AGX-V testing machine. Innovations meet new industry standards that seek automated solutions that are simple to execute.

Specialized in the manufacture of analytical instruments and mechanical testing and inspection equipment, global leader Shimadzu launches in Metallurgy the HMV-G microdurometer and the AGX-V testing machine. Innovations meet new industry standards that seek automated solutions that are simple to execute.

The new series of Vickers HMV-G30/G31 Microdurometers has functions that provide more data reliability, even meeting ISO standards. Vickers microdurometers measure hardness at minimal strength levels. A pyramidal diamond with a square base (indenter) applies a force to the sample and its hardness can be obtained by measuring the indentation formed on the surface are advantages of these analytical instruments.

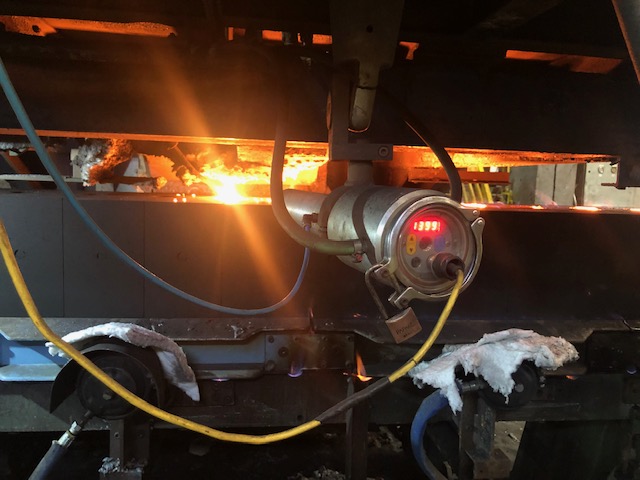

This type of microdurometer is used in a wide variety of industries for inspections of steel, metallic materials and mechanical parts, as well as for evaluating surfaces with baths and heat treatments. Thus, it is observed that there is a growing need for data management functions in analytical instruments, as well as improvements in the system’s operability to meet numerous applications.

The HMV-G30/G31 series is compatible with measurements at low loads according to ISO standards, for Vickers hardness tests. These analytical devices have functions to increase the reliability/protection of the data and have functions for creating reports. In addition, motorized micrometer equipment can be added to adjust the table position, and a 5 megapixel color camera, considered the best in the industry.

AGX-V series of universal testing machines

Another Shimadzu launch is the AGX-V series, which offers the highest testing capacity in the industry, along with unmatched operability and safety. These analytical instruments are high end models developed based on Shimadzu’s vast experience, acquired by the development of testing machines for more than 100 years. They feature the best sampling frequency and the best deformation control for the industry, multi-joint connections that facilitate the exchange of accessories, new controller and self-diagnosis function, which optimizes the use of equipment.

Another Shimadzu launch is the AGX-V series, which offers the highest testing capacity in the industry, along with unmatched operability and safety. These analytical instruments are high end models developed based on Shimadzu’s vast experience, acquired by the development of testing machines for more than 100 years. They feature the best sampling frequency and the best deformation control for the industry, multi-joint connections that facilitate the exchange of accessories, new controller and self-diagnosis function, which optimizes the use of equipment.

All of these characteristics give the AGX-V series an exceptionally high performance, as required by the aeronautical, composites and automobile industry. Since the manufacture of its first testing machine in 1917, Shimadzu has contributed to the R&D and quality control of the industries through its testing machines. Among the diversified line of analytical instruments and testing machines, the Autograph series stands out, which has high precision and can be used for tensile, compression and shear tests, among others.

The demand for high performance test machines has been gradually increasing. The steel industry, for example, demands precision solutions for controlling the strain rate in tensile tests on metallic materials, in order to meet the international standards required in automotive, aerospace applications, among other markets. Along with this, there is a growing demand for systems that are easy to operate, safer and have great functionality, thus ensuring data reliability. The Autograph AGX-V series analytical instruments incorporate new functions and improvements, ideal for testing materials that require large test forces, such as metals and carbon fiber reinforced polymer (CFRP).

Global leader in analytical instruments and test equipment

Shimadzu provides a wide range of analytical instruments indispensable for research, development and quality control in a variety of fields. Sophisticated, high-level instruments include chromatographs, spectrometers and elemental and surface analysis systems. It also provides a wide range of high-precision physical tests and measurement technology, essential for product development and quality assurance. Shimadzu Brasil is a representative of Shimadzu Corporation in Latin America and has more than 100 years of experience in the development and manufacture of testing machines.

Read more