Rotavi Industrial, market leader in inoculant alloys, brings its most advanced solutions to the foundry and steel industry. With a successful history marked by innovation and quality, Rotavi is recognized nationally and internationally for the excellence of its products.

Rotavi Industrial, market leader in inoculant alloys, brings its most advanced solutions to the foundry and steel industry. With a successful history marked by innovation and quality, Rotavi is recognized nationally and internationally for the excellence of its products.

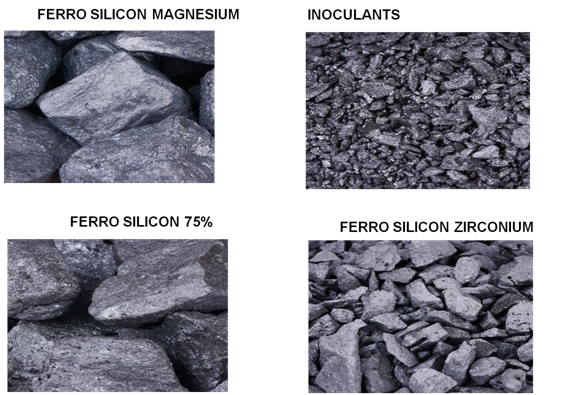

Rotavi stands out for its ability to produce alloys and inoculants that precisely meet the chemical and granulometric characteristics of each customer. Thanks to its electric submerged arc furnaces and state-of-the-art processes, the company offers highly customized products according to pre-agreed specifications. This flexibility allows customers to get exactly what they need to optimize their metallurgical processes.

One of Rotavi’s hallmarks is its commitment to elevating customer performance. Through continuous innovations and improvements, the company has a prominent presence in several markets, including North America. Rotavi’s differential lies in the high performance of its products, proven by the satisfaction of customers around the world. Through process improvements, the performance results of customers have been expanded, making them more competitive in their respective sectors.

Sustainability in the production of inoculant alloys

In addition to its focus on performance and quality, Rotavi also stands out for its environmental responsibility. The company invested in antipollutant filters that comply with current environmental legislation. This reinforces Rotavi’s commitment to promoting sustainable industrial practices, minimizing the impact on the environment.

Along with state-of-the-art production infrastructure, Rotavi offers customers expert technical support. Its research and development laboratory is an innovation center, ensuring the constant evolution of its products and adaptation to the changing demands of the market.

About Rotavi

Rotavi is a renowned primary transformation company of inputs for the metallurgical foundry and steel industries. Founded in 1972, it is located in Várzea da Palma, in the State of Minas Gerais. Its production unit is equipped with state-of-the-art technology, covering production, support and administration sectors. With a production capacity of 60 thousand tons per year of FeSi (Iron Silicon), Silicon Metal, Inoculants and special Silicon-based alloys, Rotavi is consolidated as a reference in the sector.

Rotavi’s strategic location provides significant advantages in terms of transport logistics. With highways and railways connecting the region from North to South, East to West, the company transports its production to the main ports of the country and several regions of Brazil. This privileged location streamlines the distribution of its products, benefiting its customers with efficient and punctual deliveries.