With a proposal focused on innovation and customization, Ztech has positioned itself as a benchmark in the production of dense, insulating and special high-performance refractory solutions, always with a focus on performance and sustainability. At Metalurgia, the company is presenting its range of refractory concretes (conventional, low and ultra-low cement, cement-free), repair mixes, bricks, mortars and special pieces. It is also exhibiting its exclusive colloidal mullite concrete, a solution that combines thermal and mechanical resistance with excellent cost-effectiveness.

Ztech serves an extremely wide range of industrial sectors such as steam and power generation, chemicals and petrochemicals, glass, frits, cement, lime, iron, steel, aluminum, copper, zinc, tin, lead, among others. The brand’s refractory solutions can be used in a variety of industrial equipment such as boilers, dryers, heat treatment furnaces, electric arc and induction furnaces, biomass, oil and gas furnaces, cubicles, calciners, regenerators, incinerators, strong acid and base tanks, metallurgical pans, crucibles and liquid metal transfer systems.

Each application of refractory solutions requires a specific set of thermal, mechanical and chemical properties, which is why Ztech takes an individualized approach, developing tailor-made materials to maximize durability and operational efficiency in each case.

DIFFERENTIALS OF REFRACTORY SOLUTIONS

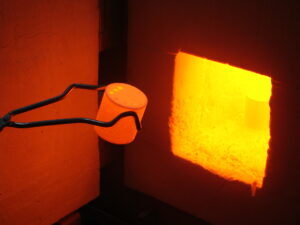

Among Ztech’s differentials in the development and supply of refractory solutions is its colloidal mullite concrete. This unique technology offers excellent resistance to thermal shock, thermal fatigue, abrasion and mechanical impact, making it a strategic choice for severe applications. In addition, it provides a significant reduction in refractory consumption over time, which directly implies less waste generation, less environmental impact and more savings for the customer.

The formulation of this concrete takes into account years of practical experience and the technical knowledge of chemical and mechanical specialists. The result is a highly efficient product with excellent adhesion, easy application and a long service life, essential characteristics in aggressive industrial environments.

Another of Ztech’s great differentials is its tailor-made production line. The company manufactures refractory solutions, designs the application according to demand and carries out complete inspection, installation and maintenance services. In other words, it delivers complete solutions, integrating product and service in a single supplier, guaranteeing more agility, efficiency and safety for the customer.

ABOUT ZTECH

Consolidated in the market as a supplier of refractory solutions with innovation and customization, Ztech is constantly evolving. It is committed to continuous improvement in products and the entire customer experience. The company invests in research and development, updates its processes with the best practices of industry 4.0 and maintains a highly trained technical team, ready to meet the most complex challenges of the refractory industry. The basis of Ztech’s success lies in the combination of top-quality raw materials and cutting-edge technology applied to industrial processes. The company has mastered the critical variables of refractory performance, from controlling the melting point of minerals to the ideal chemical composition to withstand acid or alkali attacks, for example.

This expertise allows Ztech to develop exclusive solutions for extreme conditions, such as furnaces operating at extremely high temperatures or tanks dealing with highly corrosive compounds. The use of special materials, such as colloidal mullite, combined with the optimized formulation of concretes and putties, ensures greater structural stability and less wear and tear in service.