As the global manufacturing landscape continues to evolve towards smarter, lighter, and more sustainable solutions, Metalurgia 2025 will once again be a key stage for the companies pushing the boundaries of innovation incluiding mold solutions suppliers. Among the exhibitors leading this transformation is Superband, a company that has redefined what it means to be a mold solutions supplier in the aluminum alloy casting industry.

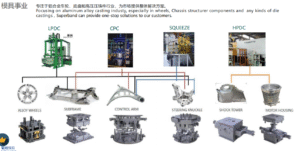

Rather than simply producing molds, Superband positions itself as a high-performance mold solutions provider, leveraging its expertise to help clients achieve lighter, more efficient, and cost-effective casting outcomes. Their participation at the fair will highlight their commitment to integrated technologies that span the full chain of aluminum alloy casting, from materials research and product design to casting process optimization and advanced tooling systems.

With over three decades of experience, Superband arrives at the event as a supplier and a strategic partner for industries seeking competitive edge through innovation and precision.

HIGH-PERFORMANCE MOLD SOLUTIONS TO CASTING INDUSTRY

Superband will showcase its integrated die-casting solutions with a clear focus on how mold innovation can reduce product weight and production costs, two of the most critical factors in today’s competitive industrial landscape. Their high-performance molds are designed not only to produce complex aluminum alloy parts with precision but also to enhance the efficiency of the entire casting process. Visitors to their stand will have the opportunity to understand how their “one-stop service” model transforms production lines by streamlining the entire product lifecycle — from conceptual design and simulation to mold and small batch production.

In sectors like automotive, where electrification and sustainability are reshaping vehicle architecture, lightweight design has become a cornerstone of innovation. Superband plays a crucial role in this transition by enabling optimized aluminum casting solutions through cutting-edge mold technology.

Their tools are built to ensure dimensional accuracy, consistent microstructure, and extended tool life, all while supporting complex geometries and high-volume production. This level of performance is achieved through advanced mold design and simulation, tailored cooling and thermal regulation systems, precision machining and surface finishing and integrated quality control processes. These features allow manufacturers to reduce scrap rates, lower energy consumption, and achieve higher productivity, ultimately driving more sustainable and profitable operations.

ABOUT SUPERBAND

Founded in 1990 in Foshan, China, Superband has grown into a global reference in aluminum alloy die-casting and mold development. The company has built its reputation on the strength of its technological integration, providing full-chain solutions that go far beyond conventional tooling. By investing heavily in R&D, Superband merges deep knowledge of material behavior with advanced casting techniques and tooling innovation. The result is a value proposition that reduces weight, enhances mechanical performance, and delivers optimized cost-benefit ratios for clients across multiple sectors.