The foundry industry is experiencing a moment of profound transformation, driven by new technologies, digitalization and the growing demand for more efficient, safe and sustainable processes. In the midst of this scenario, SENAI Santa Catarina’s participation in Metalurgia 2025 will be a strategic opportunity to demonstrate how professional education, applied research and incremental innovation can be important allies in the construction of the Foundry of the Future.

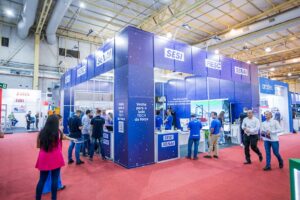

Nationally recognized as one of the main engines of industrial development through education and technology, SENAI SC will present at the fair a booth fully focused on integrated solutions for the foundry and services sector, with emphasis on tools that support digital transformation in the sector’s industries. SENAI SC is dedicated to the main demands of the industry aimed at professional training, development of technological solutions and support to the industry in its modernization challenges.

The technical training promoted by SENAI prepares new talents for the market and updates the knowledge of professionals already working, which is essential in a scenario where technologies evolve rapidly. In addition, the institution offers courses customized to the specific needs of the industry, including topics such as digital casting, predictive maintenance, automation, welding, quality, and lean manufacturing.

In practice, SENAI acts as a link between the challenges faced by the industry and the solutions that can be implemented with the support of technical knowledge, applied research, and cutting-edge technologies.

TECHNOLOGY FOR THE FOUNDRY OF THE FUTURE

With an eye on the Foundry of the Future, SENAI SC will present technologies and methodologies that integrate innovation into the industry’s routine. In reverse engineering, it applies the technique that allows the digital reconstruction and redesign of industrial parts from physical samples, using technologies such as 3D scanning and CAD modeling. This approach is essential for factories that need to maintain production even in the face of unavailability of original designs or suppliers.

In the digitalization of processes, it acts in the transformation of production stages through the collection and analysis of data in real time, promoting greater quality control, traceability and operational efficiency. Digitalization also serves as a basis for the implementation of predictive systems and the use of artificial intelligence in production management.

Incremental innovation is present in the presentation of practical, low-cost and high-impact solutions, which can be immediately applied in the production lines of companies. It is a viable path for small and medium-sized industries that want to innovate and expand the use of technology without large investments, but with measurable results.

In the area of Occupational Health and Safety (OSH), SENAI will also demonstrate solutions aimed at improving working conditions in industrial environments, with emphasis on preventive actions, occupational risk management and workers’ well-being, factors that are directly related to productivity and team engagement.

ABOUT SENAI SC

SENAI Santa Catarina is one of the main institutions supporting industrial development in the state and in Brazil, acting with excellence in professional training, applied research, innovation and technology. With a modern structure and connected to the needs of the market, SENAI SC trains thousands of professionals annually and develops tailor-made solutions for industries of all sizes and sectors. In addition to technical and technological education, the institution stands out for its performance in engineering projects, digitalization of processes, health and safety at work, contributing directly to the increase in productivity, competitiveness and sustainability of Santa Catarina and national companies.