One of the global leaders in high-performance solutions, Saint-Gobain, confirms its participation in Metallurgy where it presents the innovations of the ZirPro and Abrasive Grains units, specialized in zirconia spheres and grains. These solutions are applied in surface treatment by blasting, such as cleaning, preparation, finishing and shot peening of industrial parts and components.

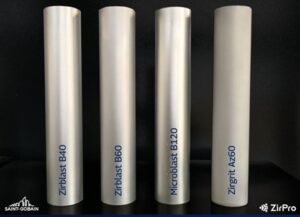

During the fair, Saint-Gobain will highlight the technical and operational differentials of its zirconia spheres and grains, used by industries demanding in terms of surface quality, precision and efficiency. Developed with a high degree of technology, these materials have been successfully applied in the metallization, thermal spraying, automotive, aeronautics, electronic, biomedical (implants) sectors, as well as in molds and dies of the most varied types such as glass, rubber, plastic injection, extrusion, among others.

The use of zirconia as a blasting medium offers significant gains in productivity and performance. Thanks to their high wear resistance, ZirPro and Abrasive Grains spheres and grains stand out for having a much higher durability compared to traditional media on the market, which provides a significant reduction in abrasive consumption over time.

In addition to direct savings in the process, the extended durability also results in less need for replacement, less waste generation and more operation time with high performance. This translates into reduced cost per cycle, as well as a more homogeneous surface finish with greater roughness control, which is essential in high value-added applications.

ADVANTAGES OF BLASTING WITH ZIRCONIA BEADS AND GRAINS

By utilizing Saint-Gobain ZirPro and Abrasive Grains’ zirconia beads and grains, companies find a more efficient and technically superior solution for operations. The process is superior in cleaning parts with removal of oxidation, scale or industrial residues without changing the geometry of the part. Another advantage is in the preparation of surfaces for painting, coating or other treatments, ensuring greater adhesion and final quality.

The technical finish of the blasting with zirconia beads and grains results in high uniformity and refined visual aesthetics. In addition, the balls are efficient in shot peening, a treatment that improves the mechanical properties of metal parts, such as resistance to fatigue and stress corrosion, by inducing compressive residual stresses.

All these processes gain superior quality when performed with ZirPro’s zirconia materials, which ensure tighter control of granulometry, hardness and sphericity, three critical factors for the standardization and reproducibility of results.

SUSTAINABILITY APPLIED TO PROCESSES

In addition to technical excellence, Saint-Gobain stands out as a world reference in environmental responsibility. The ZirPro and Abrasive Grains units are aligned with the group’s global commitment to carbon neutrality, through the Net Carbon Zero 2050 program. This means that the entire value chain, from production to final application, is guided by sustainable practices and the reduction of the environmental footprint.

One of the highlights in this journey is the creation of the company Valoref, also part of the Saint-Gobain group, specialized in the reprocessing of ceramic waste, especially zirconia spheres used in blasting, and other abrasives and refractories. This integrated recycling solution allows customers of the group’s Ceramic Materials units to have a sustainable alternative for the disposal of their inputs, promoting the circular economy and reducing the use of natural resources.

ZirPro’s plant was recognized in 2024 with the EcoVadis Platinum Medal and the Deng Feng Grain Plant in 2023 as well, one of the most important international certifications of corporate sustainability. This achievement reinforces the company’s ongoing commitment to ESG (environmental, social, and governance) practices and its role as a trusted provider of sustainable solutions to the industry. It also has several products with LCA (Life Cycle Assessment) and EPD (Environmental Product Declaration) available.

ABOUT SAINT-GOBAIN

With a history of more than 360 years, being the fifth oldest registered company in the world, the Saint-Gobain Group brings together tradition, innovation and a global performance that impacts various industrial sectors. Focusing on the production of zirconia beads, grains and powders, it has been consolidating itself as a reference in quality, performance and sustainability, being a strategic partner of more than 160 thousand employees and thousands of companies around the world.