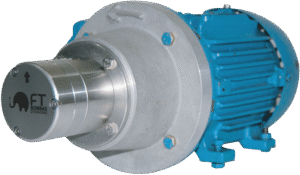

A reference in industrial pumping solutions, FT Bombas takes to the Metallurgy Fair its line of gear pumps with magnetic coupling, a technology that transforms the way fluids are dosed and transferred accurately and safely in the most demanding industrial environments.

The highlight of the participation will be the direct application of the pumps in the sand/resin molding process, typical of modern foundries. FT Bombas’ magnetic metering pumps provide very high precision in the dosing of resins and catalysts in continuous mixers, ensuring stability and control in a process where the accuracy in the proportion of components directly impacts the final quality of the mold and, consequently, the cast part.

In addition, the company presents its new line of magnetic transfer pumps, specially developed for the safe movement of aggressive and viscous fluids such as resins and catalysts, from storage tanks to mixer reservoirs. With this, FT Bombas delivers a complete solution for the supply and dosing cycle in the sand/resin process, expanding quality control and reducing operational losses.

DIFFERENTIALS OF MAGNETIC COUPLING TECHNOLOGY

The great differential of FT pumps is the replacement of conventional sealing systems by a magnetic coupling, which eliminates the risk of leaks and ensures a fully sealed, safe and low-maintenance operation. This characteristic is especially critical in environments such as foundries, where the presence of chemical compounds requires high reliability and safety.

By eliminating the leakage points common in traditional pumps, this technology offers benefits such as:- Zero contamination of the environment or the pumped fluid;- Reduction in maintenance costs and machine downtime;- Increased durability and reliability of the system;- Enhanced safety for operators and processes.

ABOUT A FT PUMPS

With a solid trajectory in the industrial sector, FT Bombas stands out for its 100% national manufacturing capacity and total control of the production chain, which allows for tailor-made deliveries, continuous technical support and high quality standards. The company acts as a strategic partner to its customers, offering tailor-made solutions for critical dosing and transfer processes, especially in the areas of foundry, chemical, polyurethane and food.