Specialized in the production and supply of filtering elements with the most advanced technologies, Advancetex Internacional exhibits at Metalurgia the portfolio of products produced with high quality materials to guarantee efficiency and durability in industrial filtering processes. The product line includes filtering sleeves and cages, screens and mats for liquid filtration, canvases for pneumatic transport/air slides, fluorescent powder for leak detection, rubber profiles for seals and fabrics for Press Filters.

Specialized in the production and supply of filtering elements with the most advanced technologies, Advancetex Internacional exhibits at Metalurgia the portfolio of products produced with high quality materials to guarantee efficiency and durability in industrial filtering processes. The product line includes filtering sleeves and cages, screens and mats for liquid filtration, canvases for pneumatic transport/air slides, fluorescent powder for leak detection, rubber profiles for seals and fabrics for Press Filters.

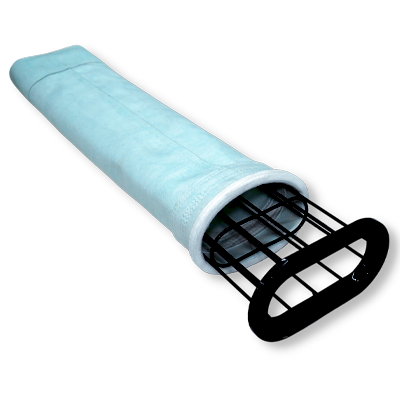

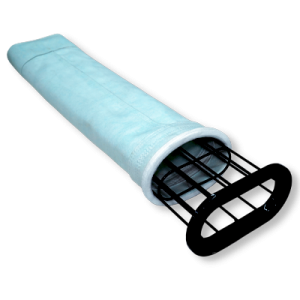

Advancetex Internacional works with the best filtering sleeves on the market, guaranteeing quality in fabric and in the manufacture of parts for pollution control. Filter elements are supplied to companies in a wide range of segments, such as mining, cement, metallurgy, aluminum, steel, ceramics, fertilizers, chemicals and derivatives, sugar, ethanol, food, effluent treatment, waste and sanitation, batteries and power generation.

SOLUTIONS IN FILTERING ELEMENTS FOR DIFFERENT DEMANDS

The variety of filtering elements produced and supplied by Advancetex Internacional meets the most different needs of industries and has different technologies, according to the application of each client.

Advancetex Internacional has a production line of filtering bags, designed to meet applications that demand high technology and efficiency products. The filter bag line includes options in polyester, polypropylene, homopolymer acrylic, PPS (with PPS or PTFE base), meta-aramid, polyimide P84 (with P84 or PTFE base), PTFE (with or without P84 layer), glass and special composite materials. The filtering bags are custom-made, according to the needs of each equipment and application.

Ad-Flow® filtering elements are an economical and effective alternative for increasing the filtering area in bag filters. They are applied in filters that have problems of high pressure differential or that need greater flow to meet new process demands. They allow up to 85% increase in the filtering area, do not require modification to the bag filter, can be applied in high temperature filters (up to 260°C) and increase the filter capacity with a simple bag change.

The filter cloths also have fully vertical and controlled production, from the monofilament yarn to the finished product for different applications. Advancetex Internacional has a complete line of Ad-Link meshes, with spiral construction, with different combinations of wires with diameters from 0.60 mm to 1.10 mm. They can be made of polyester or PPS without filling yarn, with circular or rectangular profile filling yarn (flat yarn). The woven screens are produced in different materials, permeabilities, weights and patterns (single slab, double slab, canvas, twill, satin, among others).

For the weaving of the screens, Advancetex Internacional produces polyester, polypropylene, nylon and also PPS threads, resistant to temperatures of up to 190°C. It also offers splicing options with metallic staples, spiral, Pin-Seam and endless splicing.

DISTRIBUTOR OF FILTERING ELEMENTS FROM OTHER BRANDS

Advancetex International is a distributor of Fluitex tarpaulins for pneumatic transport (air slide), manufactured by the German company Mühlen Söhn. They are available in polyester and aramid, in different permeabilities and thicknesses, and are custom-made to facilitate installation.

Advancetex International also distributes the high performance PulsePleat® Pleated Sleeves manufactured by Parker (BHA). They can be manufactured with rigid steel or flexible polyurethane collars. The iPLAS® type straps used in the body of the filtering element guarantee the firm anchoring of the pleats, maintaining the spacing and alignment during operation. Filter media and constructions are available for both low and high temperature application, with or without an ePTFE membrane.

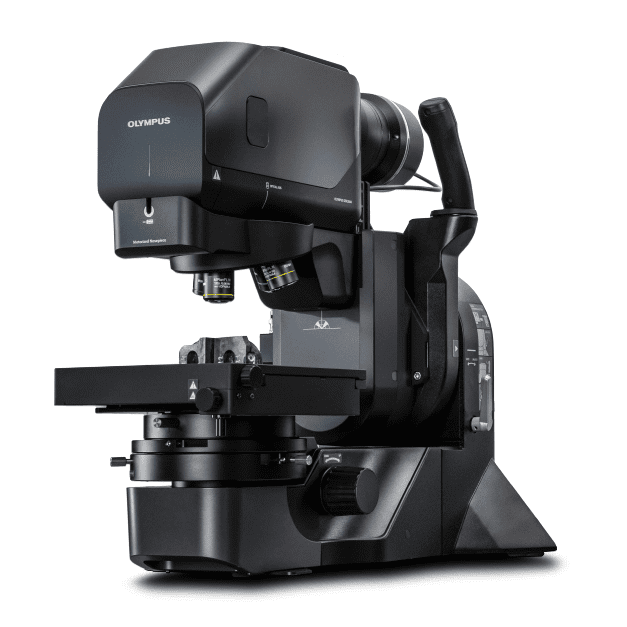

Finally, Advancetex Internacional also supplies the fluorescent pigment for detecting leaks in bag filters. The test consists of injecting the fluorescent powder at a point before the bag filter. After injecting the powder, an inspection is carried out in the clean filter chamber, with the aid of a UV light that highlights the leak points. The procedure ensures time savings in leak detection, greater availability of the filter for production, occupational health and safety and less demand from the operator inside the filter.

ABOUT AVANCETEX INTERNATIONAL

Advancetex International is a global company with over 100 years of industrial experience in air pollution control, liquid filtration in industrial processes and process optimization. The company’s mission is to provide filtering elements, fabrics for press filters and accessories of a high level of quality and reliability, promoting efficiency and durability superior to the market average. We are present in the largest national industrial groups and we serve all of Latin America from our unit in Indaial-SC.